Light Gauge Steel Frame Machinery

| Summary | ||

| 1). To design and make the best roll forming machine, we took EUROPEAN quality standard; | ||

| 2). Choose the best material and components, and adopting our 17+ years experience; | ||

| 3). We achieves that the machine capacity is double of the competitors; | ||

| 4). The machine working speed can be 60m/min; | ||

| 5). Very easy to install and operate the roll forming machine. | ||

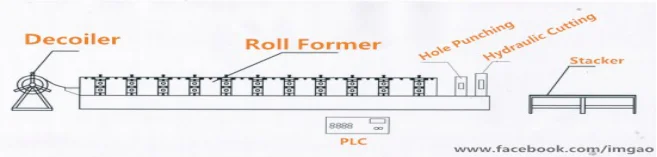

| Machine working flow: |

| Machine Technical Specifications: | ||

| About raw material and product for roll forming machine | ||

| Material&product | Feeding width | according to profile |

| Effective width | according to profile | |

| Raw material | galvanized steel strip | |

| Thickness | 0.3-0.7mm | |

| Yield strength | 280-350 MPA | |

Raw Material:

G550

| How to load the material→Decoiler | ||

| Manual decoiler | Inner diameter:450-550mm | Expand by band |

| Outer diameter:1500mm | ||

| Max Coil width:300mm | ||

| Capacity: 1.5T | ||

| Decoiler dimension:1.5*1.5*1.5m | ||

| Decoiler weight:355KGS | ||

| Quantity: 1set | ||

| Usage: It is used to support the steel coil and uncoil it in a turntable way. | ||

| Passive uncoil pulled by roll forming system | ||

| What the main forming machine will be→as below | ||

| Main Forming machine | Forming steps | 12 steps |

| Shaft diameter | 50mm | |

| Machine stand | Individual Arch Plate | |

| Machine frame | steel plate welded | |

| roller material | Cr12 | |

| shaft material | 45# steel with quenching and tempering | |

| Work speed | standard: 20---25m/min; 45---60m/min | |

| Transport | By gear | |

| Power of main machine | 4kw | |

| Voltage | 380V-50HZ-3P(as required) | |

| Machine dimension | 5.5*0.8*1.5m | |

| Machine weight | About 2.5T | |

| Machine color | Yellow and blue(as required) | |

| Usage: In order to keep the product shape and precision, adopts welded sheet structure, | ||

| motor reducer drive, chain transmission,roller was chromed which can keep the | ||

| molding plate surface smooth and not easy to be marked when it is working | ||

| Feature : Ensure stability , precision and lifetime. | ||